Key Takeaways

- Preventive maintenance involves proactive steps such as cleaning, aligning, and replacement of worn components. This will help make sure that printers are always running smoothly and producing the best quality prints available.

- Dirty printheads, low ink or toner, misaligned cartridges, paper feed issues, and incompatible supplies can all cause print quality issues. These issues are some of the most common, and they can almost always be avoided with regular maintenance.

- With routine cleanings of printheads, inspection of essential parts, and calibration of components, you can ensure your printer is used for much longer. These regular maintenance tasks help prevent unexpected breakdowns as well.

- Preventive maintenance starts with using manufacturer-approved ink, toner, and parts to ensure optimal print quality. This practice further prevents compatibility issues that can damage your printer.

- Implementing best practices, such as scheduling maintenance, monitoring usage, and training staff, helps businesses maintain optimal printer performance and avoid costly repairs or downtime.

- If you’re struggling with poor print quality or constant breakdowns, preventive maintenance could be the solution. They offer on-demand, specialized expertise when DIY troubleshooting just won’t cut it.

When you’re struggling with poor print quality, it’s usually a sign that maintenance has been neglected. Preventive maintenance helps solve frequent problems such as streaks, faded prints or misaligned text by ensuring printers are always running at peak performance.

Preventing performance issues involves regular cleaning of print heads, alignment of cartridges, and inspection of common wear and tear items. These practices keep everything running like new. Dust accumulation and dried ink are common offenders, but regular maintenance reduces these issues.

Even simple steps, like using high-quality paper and checking rollers, make a big difference in output. By proactively scheduling routine maintenance, you not only increase the lifespan of your printer but also help avoid costly and unexpected printer breakdowns.

These practices lead to significant cost savings, not only in reduced repair costs,but in greater operational efficiency. By taking these proactive measures, you can drastically improve print quality and ensure your equipment continues to operate reliably.

What Is Preventive Maintenance

Preventive maintenance is the first step towards keeping your equipment, including printers, healthy and performing at peak levels. It means committing to regular preventive maintenance of these machines. This new strategy is a proactive step.

It addresses issues before they become major concerns, enabling more reliable operations with increased uptime and performance. Printer preventive maintenance usually consists of regular maintenance visits and basic maintenance procedures.

These measures prevent costly downtime, prolong the life of the printer, and ensure overall reliability.

Definition Of Preventive Maintenance

Within printer maintenance, preventive maintenance means scheduled maintenance routines established to prevent malfunctions and quality concerns. This could mean regular cleanings of the printheads, preventing buildup of debris on internal parts, making sure the rollers aren’t worn down, etc.

Prioritizing these tasks through a scheduled basis prevents printers from running ragged, causing wear and tear in the long run. For instance, preemptively cleaning a laser printer’s fuser on a regular basis prevents toner accumulation, guaranteeing clearer print jobs and more efficient performance.

Purpose Of Preventive Maintenance For Printers

The ultimate objective is to ensure consistent print quality and performance with the least amount of downtime. Preventive maintenance, like replacing an inkjet printhead or recalibrating color settings, goes a long way toward reliable output.

A well-maintained printer produces cleaner, smudge-free documents, causing fewer disruptions in productivity due to downtime. Businesses immediately see reduced mistakes and more durable machinery when using preventive maintenance.

Key Components Of Preventive Maintenance

This is a more involved process that involves cleaning, inspecting components, and using only the best materials, such as OEM cartridges. Daily routine cleaning keeps dust from accumulating, and visual inspections help detect problems before they can develop into a more serious issue.

About the importance of using the proper supplies to prevent clogs and ensure long lasting performance.

Common Causes Of Poor Print Quality

These factors range from the printer’s state of mind to a wide variety of outside forces affecting common printer issues. Knowing why these problems occur and how to fix them will help you maintain a reliable printer with uniform, professional-looking output. Here, we dive into a few of the most common offenders and preventative maintenance tips to address them.

Dirty Or Clogged Printheads

One common cause of poor print quality is clogged or dirty printheads, which can lead to streaking, smudging, or faded prints. Ink can dry, or residue can build up when the printer is left unattended for long periods of time. This accumulation can result in multiple print quality problems.

Routine maintenance is just as crucial to your printer’s health. Either use built-in printer utilities or clean manually with a lint-free cloth dampened with distilled water. Failure to perform this maintenance can result in irreparable damage to the printheads and greater repair costs.

Low Or Expired Ink Or Toner

Low ink or toner can cause prints to appear faded. If your ink or toner is out of date, you’ll get poor results with that too, including pitiful print quality. Consistently monitoring ink levels and replacing cartridges before they run all the way out is key.

This practice helps ensure optimal print quality as well as protect the printhead from damage that may occur from running on empty.

Misaligned Printer Cartridges

Misaligned cartridges usually result in jagged text or images. Most printers have an alignment tool available in their settings, which takes you step-by-step through the realignment process.

Making sure that cartridges are installed correctly when replacing cartridges prevents alignment issues and helps keep print quality at its best.

Paper Jams And Feed Issues

Paper jams are usually the result of feeding multiple sheets, poor paper quality, or printing stapling documents. Preventing feed problems by not overloading the output tray and using high-quality, smooth paper will help.

Making it a point to inspect and clean feed rollers on a regular basis will help your printer operate more smoothly with less interruption.

Incompatible Or Unsupported Cartridges

Using incompatible cartridges may result in poor print quality or a printer error. Using cartridges that are OEM-approved for your printer will save you time and headaches with failed prints.

These cartridges are tailored for the printer’s entire ecosystem, minimizing the chance of quality degradation or hardware damage.

How Preventive Maintenance Addresses Print Issues

Preventive maintenance is an effective solution to addressing bad print quality and keeping printers running with less downtime. Preventive maintenance addresses problems while they’re still small. This proactive approach does far more than improve the quality of your print—it can drastically increase the lifespan of your equipment.

Here are the key elements of preventive maintenance explained.

1. Cleaning And Servicing The Printer

Keeping a regular cleaning schedule is the first step to printer preventive maintenance. Begin by dusting external surfaces with a lint-free cloth to prevent dust from accumulating. Perform preventative maintenance, keeping the internal components—including the paper rollers—free of debris.

Running the print head cleaning function on your inkjet printer prevents printhead clogs. This is critically important for Epson models as even one clogged nozzle can throw colors out of whack. Follow cleaning with periodic professional servicing to address hidden concerns that can come up.

Preventive tip: Maintaining a clean, dust-free environment protects the printer from contaminants that may impact performance.

2. Aligning And Calibrating Printer Components

Alignment makes sure that all the printer’s moving parts, especially the print heads and rollers, operate in alignment and concert. Misalignment leads to blurred text or skewed images. Most printers come with built-in calibration tools that protect against print inaccuracies and run these monthly.

Properly aligned components help ensure sharpness and accuracy in printouts, preventing costly mistakes and time spent on reprints.

3. Replacing Worn-Out Parts Regularly

Find components that are wear items, like feed rollers, fusers in laser printers, and print heads in inkjets. Defective fusers, for instance, can lead to smudging from improper heat levels. Regular and timely replacement keeps your equipment from breaking down, causing a loss of productivity and workflow.

Developing a proactive replacement schedule allows you to keep an eye on the essential parts of your print fleet and replace them before failure occurs.

4. Ensuring Proper Ink And Toner Usage

Always use the right ink or toner for your printer model. Streaky printouts and fading images are avoided with high-quality ink, and keeping an eye on levels ensures projects aren’t interrupted mid-task. Frequent inspection for cartridge communication errors, which are frequently due to soiled contacts.

Regularly shut down printers to ensure cartridges are stored in a sealed position, preventing drying out.

5. Managing Paper Feed Systems Effectively

The dreaded paper jam is one of the biggest print nuisances, but it doesn’t have to be. Make sure your paper weight and type are compatible with your printer to avoid misfeeds. Keep feed rollers clean and check for signs of wear.

By testing paper alignment before loading, the risk of feed-related issues is decreased, helping to maintain smooth operations.

6. Resolving Connectivity And Software Issues

Connectivity issues are often caused by outdated printer drivers or network configurations. Prevent software issues with preventative measures. Regularly updating drivers ensures that programs remain compatible and can help troubleshoot issues quickly.

Dealing with these concerns upfront will lead to a more seamless print infrastructure without any downtime and improved compatibility with other devices.

7. Maintaining Optimal Operating Conditions

Environmental factors can greatly affect the performance of printers. Store printers in a clean, dry, stable environment with a temperature between 60°F and 75°F and humidity level of about 40%.

By controlling these conditions, we protect the integrity of internal components, providing long-term reliability.

Benefits Of Preventive Maintenance For Businesses

Taking the time to implement preventive maintenance can be incredibly rewarding for businesses, particularly those faltering under the weight of bad print quality. By prioritizing preventive maintenance, businesses can ensure their operations maintain smooth and uninterrupted performance while avoiding costly disruptions and resource wastage.

Here, we’ll further discuss how preventive maintenance directly affects productivity, safety, and cost, protecting the bottom line in the long run.

Enhanced Print Quality Consistently

Preventive maintenance is the key to maintaining the highest level of print quality. It addresses issues such as clogged nozzles, worn rollers, and misaligned components before they develop into major failures. It’s the best way to make sure your prints are always the sharpest, most professional-looking.

Routine PMs eliminate printing problems, like smears and streaks, that can ruin output quality before the end user even sees it. In knowledge-based industries such as marketing and legal services, consistency of product or service delivery is key to quality assurance. It helps to build trust and retain clients.

Reduced Downtime And Operational Delays

Unscheduled downtime doesn’t just hurt your workflows, it can hurt your bottom line too. Preventive maintenance helps avoid these interruptions by catching potential failures before they occur.

Additionally, businesses can plan and schedule maintenance during off-peak hours of operation, maintaining a continuous level of service. The method minimizes added costs due to going off schedule, since equipment is more reliable and not out of service, so deadlines are met every time.

Increased Printer Lifespan And Durability

Well-maintained printers have a longer lifespan, which can prolong their useful life and push back the time to replacement. When businesses invest in routine care, they ultimately save on long-term costs, since at a minimum, well-maintained printers break down less frequently.

This long-lasting durability protects the upfront investment, delivering ongoing savings year after year.

Cost Savings On Repairs And Replacements

Preventive maintenance saves repair costs by fixing small problems before they become big ones. Replacing a worn belt during a planned service is relatively inexpensive.

In comparison, repairing a failed motor from lack of care can be far more costly. Preventing major equipment failures keeps expensive replacements at bay, so preventive care is a winning financial strategy.

Improved Productivity And Workflow Efficiency

When businesses keep their printers well-maintained, they realize the benefit of seamless workflows by preventing business interruptions. When equipment is reliable, employees can focus on doing their work without wasting time dealing with breakdowns.

This reliability increases morale, as staff can rely on their tools, increasing efficiency and productivity company-wide.

Best Practices For Printer Care

Preventative printer care is the pillar of getting reliable performance, maximizing printer lifespan, and delivering quality prints. Take a methodical approach to avoid avoidable decays. It will go a long way in reducing ink and paper waste, and help you get the most from your printer.

Here are some printer maintenance best practices to keep your printer working at its best.

Schedule Regular Cleaning And Inspections

A regular cleaning routine removes dust, ink residue and other debris that can affect print quality if allowed to accumulate. PiezoFlush carts make low-use printers more successful. After deploying these carts, run the printers through 2 cleanings and they can sit unused for a year with no adverse effects.

Routine inspections identify worn or aged parts in advance, minimizing the chances of unexpected downtime. Setting reminders for these tasks helps to make sure they’re not forgotten, particularly in bustling work environments.

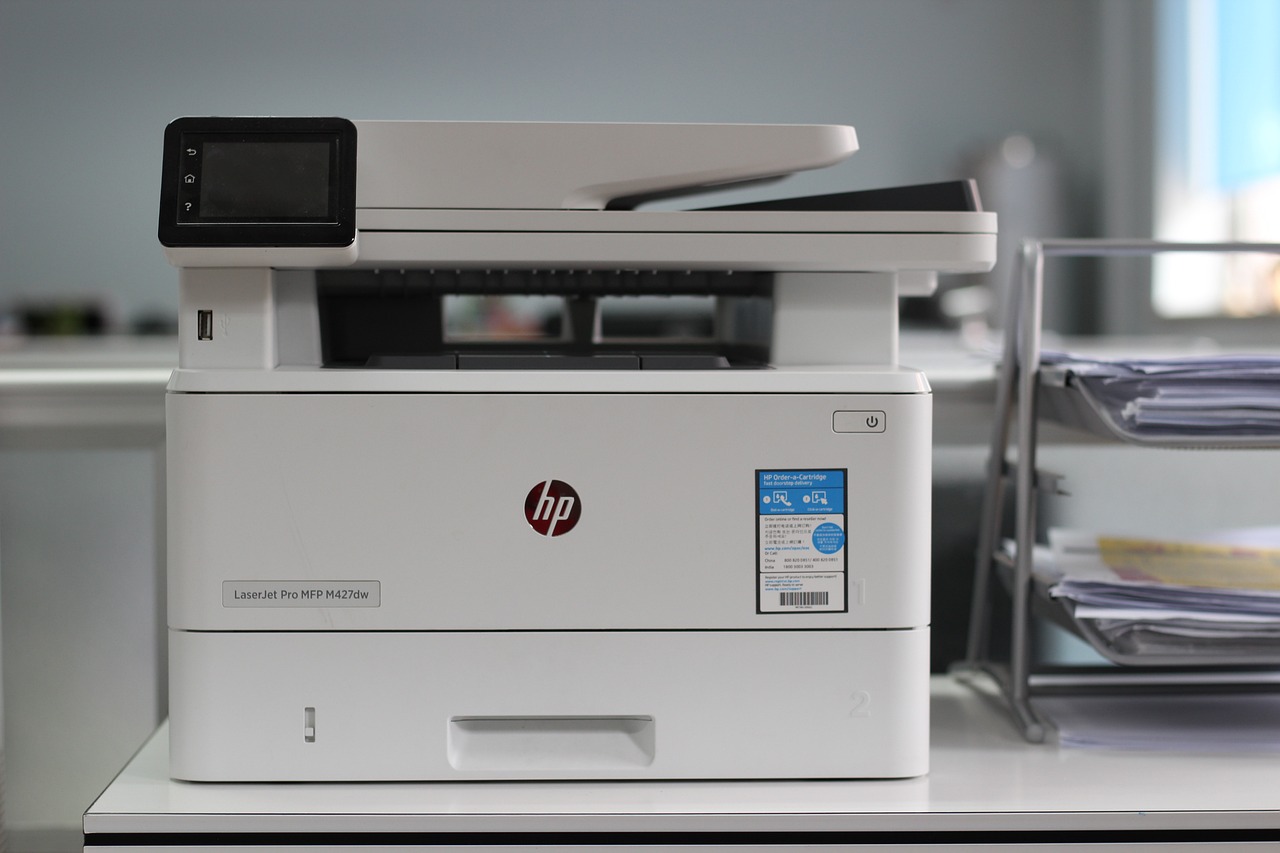

Use Manufacturer-Approved Supplies

When you use manufacturer-approved supplies, such as genuine HP ink or toner, you’re guaranteed optimal print quality and to avoid compatibility issues. Generic or third-party products usually look more affordable, but they can cause clogs or physical damage.

Always check compatibility before buying, as this one easy step can avoid costly repair fees.

Store Printers In Controlled Environments

Printers are sensitive machines that work best in stable environments. Excessive heat can harm internal equipment, while high levels of humidity lead to paper jams. When not in use, keep printers in an area with stable temperature and humidity.

Or better yet, keep them off during extended downtime, such as holidays, to prolong their overall performance.

Monitor Printer Usage And Wear

Tracking usage patterns highlights when regular printer maintenance is needed. For example, rotating between two multifunction printers during 24/7 operations reduces strain on individual machines. Regularly assessing print speeds, like 22 ppm for black and 18 ppm for color, can reveal common printhead problems over time, prompting timely interventions.

Train Staff On Proper Printer Handling

Training staff to use printers properly is essential for reducing mistakes and prolonging the life of reliable printers. Developing easy-to-follow instructions for tasks like double-sided printing or printing multiple pages per sheet can significantly reduce ink and paper usage, ultimately enhancing the overall printing experience and minimizing common printer issues.

By ensuring employees are well-trained in proper printer maintenance and settings, many printers can avoid typical problems, thus keeping offices running more efficiently and reducing the need for costly printhead repairs.

When To Seek Professional Maintenance Services

Maintaining printers to keep them running their best requires a mix of daily maintenance and professional service, including regular printer maintenance. Although most small maintenance errors can be addressed through at-home solutions, there comes a time when the expertise of a professional is necessary. Knowing what to look for and when to call in an expert can save you time, money, and aggravation, especially when dealing with common printer issues.

Signs Of Persistent Print Quality Issues

Chronic quality issues, including streaking, smearing, or fading output, may be symptomatic of more serious concerns. These may be anything from defective parts to miscalibration. Little problems, such as the odd misalignment, may be fixed with an internal adjustment.

When issues are ongoing, particularly those that hinder several functions, it’s time to call in the professionals. Having a log of patterns like the times and/or tasks the issue occurs at is crucial to help the technician identify the root cause most efficiently. For example, if an issue develops after long-term use, this might indicate wear related to hours operated.

Frequent Equipment Malfunctions Or Errors

If you’re dealing with frequent malfunctions, such as paper jams or misleading error messages, these are usually signs of more serious mechanical or software-related issues. Putting off persistent mistakes only means more expensive fixes or early equipment failure at a later date.

Repairing these quickly reduces downtime and avoids further damage. Regular inspections, particularly after periods of heavy use, can help mitigate the risk of an emergency breakdown.

Difficulty Troubleshooting Printer Problems

While basic errors can sometimes be resolved by your IT or office staff, more complex printer issues need a technician’s expertise. Red flags that troubleshooting is beyond the in-house level include stubborn error codes or intermittent operation even after address repairs have been made.

Expert maintenance is the key to correct diagnoses and lasting solutions that prevent ongoing interruptions.

Benefits Of Managed Print Services

Generally managed print services make maintenance easy by outsourcing the work to professionals. This method lessens operational wear and tear, with trained professionals taking on inspections, repairs, and proactive servicing.

With a preventive maintenance strategy based on the actual use of the equipment, organizations can avoid failures caused by overuse or lack of use. Rotating equipment usage, such as using one copier Monday through Thursday and another Friday through Sunday, increases device longevity.

In addition to enhancing efficiency, managed services provide cost savings through a decreased demand for emergency repairs and a smoother overall workflow.

How To Choose The Right Maintenance Service

Choosing the best maintenance service available is an essential part of being able to count on quality print production over the long haul. Without proactive care, you’re bound to run into issues with print quality. Working with a dedicated, capable maintenance provider is one of the best ways to address this challenge.

Here are some ways to help you determine which one is the best fit for your needs—considering everything from specialized expertise to customer reviews. Here are some important things to keep in mind:

- Evaluate service provider expertise and experience.

- Compare service plans and pricing options.

- Consider response time and support availability.

- Check for customer reviews and testimonials.

Evaluate Service Provider Expertise And Experience

Professional printer maintenance provides the knowledge and experience to spot risks before they start and fix them with confidence. Experienced providers providing commercial maintenance staff often possess specialized knowledge, particularly when dealing with specialized and complex high-end equipment.

For example, if you have high-volume printers to manage, this can take a specialized skill set that not every provider has. Requesting and reviewing references or relevant past case studies gives you valuable insight into their capabilities. It shines a light on their prowess in preventive maintenance optimization (PMO).

Compare Service Plans And Pricing Options

Some plans are much more comprehensive than others, providing varying degrees of protection. Some even come with predictive maintenance (PdM) options, which employ data and algorithms to forecast failures.

This method of maintenance is especially advantageous for organizations that depend on equipment uptime. Determine what you need, with a focus on detail. Steer clear of cookie-cutter answers, which often result in wasted spending or lack of full protection.

Consider Response Time And Support Availability

Fast response times are key to reducing your downtime. For example, a managed print provider with 24/7 support can help keep printers running around the clock, even when crises erupt unplanned.

Service level agreements (SLAs) specify guaranteed response times and support hours. If done accurately, this makes them an excellent evaluative tool for measuring reliability.

Check For Customer Reviews And Testimonials

Customer reviews provide an objective perspective on a maintenance provider’s quality of service. Reliability, technical expertise, and quality of customer service are just a few things reviews tend to boast about or complain about.

Reading through testimonials can give insight into how maintenance providers have addressed unique challenges, allowing you to make a more educated decision.

Conclusion

When print quality is suffering, it can throw your entire workflow out of whack and drain your bottom line. Preventive maintenance is the best way to ensure your printers are up and running when you need them. It prevents streaking, smudging, or faded text from becoming larger issues. By being proactive you ensure you are saving time, money on repairs, and downtime.

Selecting an appropriate maintenance routine is more than just an attempt to reactively address issues. It’s about knowing that your equipment will be reliable and efficient every day. Whether that’s cleaning, replacing worn parts, or scheduling professional checkups, taking preventive maintenance steps goes a long way.

If you’re struggling with poor print quality or looking to prolong your printer’s lifespan, preventive maintenance is the way to go. Taking the time to perform a little preventative maintenance today will save you the headache tomorrow. Preventive maintenance is the key to keeping your prints sharp, clear, and professional.

Frequently Asked Questions

1. What Is Preventive Maintenance For Printers?

Preventive maintenance is the proactive cleaning, inspecting, and servicing of multifunction printers to keep them running at peak performance. This approach helps avoid common printhead problems such as poor print quality and increases the longevity of your devices.

2. How Does Preventive Maintenance Improve Print Quality?

Regular printer maintenance addresses issues like clogged printhead nozzles, dust accumulation, and misaligned components. Preventative maintenance ensures a reliable printer, resulting in sharper, clearer prints.

3. What Are The Most Common Causes Of Poor Print Quality?

Other common causes of printer problems include dirty printheads, low-quality ink or toner, paper jams, and worn-out printer components. Regular printer maintenance through preventative maintenance takes care of all those issues.

4. Why Is Preventive Maintenance Beneficial For Businesses?

Regular printer maintenance decreases downtime, lowers repair costs, and maintains overall print quality, enhancing productivity and ensuring your company presents a professional appearance.

5. When Should I Perform Preventive Maintenance On My Printer?

Complete this care as often as the printer manufacturer recommends, typically every three to six months. If you notice signs of poor print quality, call for regular printer maintenance right away.

6. Can I Perform Preventive Maintenance Myself?

Sure, tasks such as cleaning printheads and changing cartridges are part of proper printer maintenance. For complex printer problems, it’s best to call in the pros.

7. How Do I Choose The Right Maintenance Service?

Find one with certified technicians, positive reviews, and a specialization in the brand of multifunction printers you use. Choosing a reputable service for regular printer maintenance can provide quality care to keep your system running long-term.

Transform Your Office With The Best High-Volume Copiers In Concord, California!

Are you searching for a reliable high-volume copier near Concord, California? Look no further! At Office Machine Specialists, we’ve been the go-to experts in servicing and selling top-notch office equipment since 1995. As a trusted family-run business, we’re committed to providing you with the best equipment options and exceptional after-sales service.

With decades of experience, choosing the right high-volume copier can be overwhelming. That’s where we come in. Our knowledgeable team will ask the right questions, understand your unique requirements, and guide you toward making smart decisions for your business. Whether you’re looking for a new machine lease or a purchase, we’ve got you covered.

We’ve witnessed the evolution of copiers from the pre-internet era to the cutting-edge digital workflow environment. Our expertise spans efficient high-volume printing, seamless scanning, advanced account control, and fleet management. Our extensive experience with all the major brands makes us the invaluable resource your organization needs.

Don’t settle for anything less than the best. Contact Office Machine Specialists today for all your high-volume copier needs. Let us help you streamline your office operations and increase your productivity!